As a summary introductory document, we invite you to click on the following link to review the "CBR-HBR Intro Document".

Overview

The Hemp-BioRefinery (HBR) was created as an extension of the Community Bio-Refineries (CBR). CBR has broad and unique capabilities as they pertain to processing plant materials – both feedstocks and biomass. This process enables the breakdown of plant materials, in a matter of minutes, to micron-sized particles – all the while using no heat or chemicals.

Circular economy

The world’s economy is currently linear:

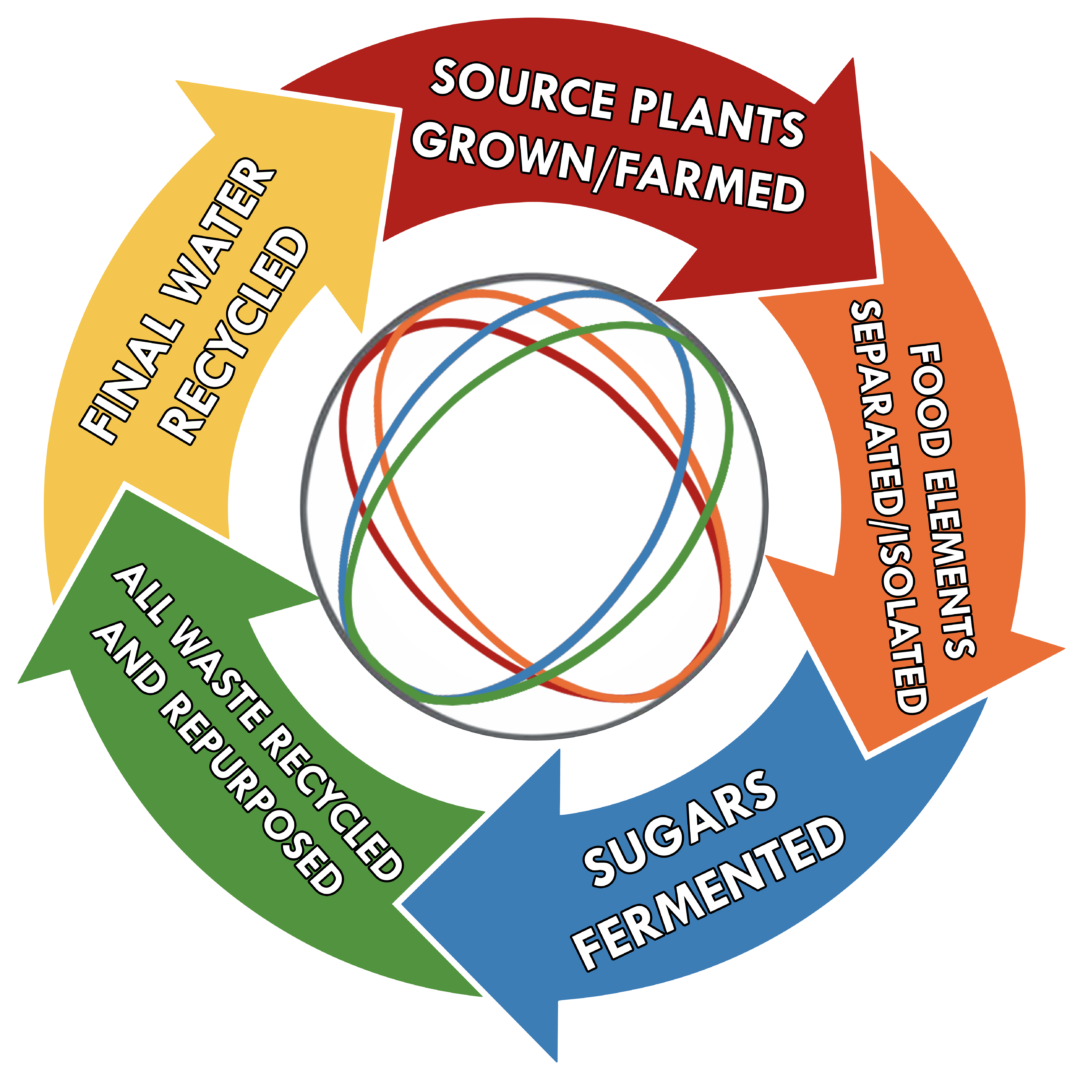

Crops are grown, farmed, processed, manufactured, sold, and then when we’re done, it is dumped into landfills. The idea of a sustainable ‘circular economy’ —one in which materials are used in a closed-loop, running on renewable energy—is gaining traction. Community BioRefineries’ vertically integrated production model is perfectly suited to support the circular economy of tomorrow.

What is a “Circular economy”?

A circular economy is an economic system aimed at eliminating waste and the continual use of resources. Circular systems employ reuse, sharing, repair, refurbishment, remanufacturing, and recycling to create a closed-loop system, minimizing the use of resources and creation of waste, pollution, and carbon emissions.

The circular economy aims to keep products, equipment, and infrastructure in use for longer periods, thus improving the productivity of these resources. Waste materials and energy become input for other processes: either a component or recovered resource for another industrial process or as regenerative resources for nature (e.g., compost) – or yet more value-added products. (Sound familiar?) This regenerative approach is in contrast to the traditional linear economy, which has a "take, make, dispose" model of production.

The Community BioRefineries model was designed long before the idea of a “circular economy” became popular. CBR uses everything, wastes nothing, recycles its final “wastewater”, and creates its own green electrical power to run its facilities.

Mission Statement

Our Mission for the Hemp-BioRefineries is to apply the research, development, and commercialization from its parent, Community Bio-Refineries LLC, to construct and operate sustainable Hemp-BioRefineries (HBRs) in local communities throughout the U.S. and internationally (where legally accepted). In using the technologies, HBRs will process the entire cannabis plant utilizing a vertically integrated process to extract all the components of the plant from the root to the bud. The HBRs will produce much higher value-added foods, nutraceuticals, and other products with the creation of advanced (third-generation) biofuels in the same biorefinery. These "New Billion-Dollar Crop" products will be produced from local feedstocks that will be sold in local markets.

HBRs will decentralize the cannabis industry, allowing each facility the ability to make quick decisions based on industry trends that can save the HBRs money overall. Decentralizing will allow the HBRs to control the day-to-day activities of your company. The HBRs primary advantage of a decentralized organization is that the HBRs will be able to make quick decisions that will save the company money. This decentralized business model was the same guide the Micro Brewery Industry utilized in the late 1980s to today when competing with the big monolith breweries. In the United States, the overall, beer volume sales were down 1% in 2018, whereas craft brewer sales continued to grow at a rate of 4% by volume, reaching 13.2% of the U.S. beer market by volume. Craft production grew the most for microbreweries. Our primary benefit of a decentralized the HBR's organization is that each facility can make quick and smart decisions that can save your company money.

The HBRs produce foods, biofuels, bioplastics, aquaculture, and energy, generating economic development in the agriculture sector, as well as in local communities. HBRs will also eliminate the use of petroleum in our local communities where HBRs are located, and reduce the cost of producing foods and the transportation of foods to the local supper table. HBRs will offer energy independence to our local communities because HBRs will serve to replace all petroleum-based products, including petroleum fuels, from diesel fuel, to gasoline, to aviation fuels.

Our Vision

Our Vision is to create networks of economically sustainable Hemp-BioRefineries (HBRs) in local communities throughout the U.S. and internationally to help establish sustainable green communities throughout the U.S. and internationally by providing food, energy in the form of biofuels and green electric power, and bio-products to help meet the goal of energy independence of local communities and our nation from foreign oil.

Our Story Hemp-BioRefineries (HBR)

The Hemp-BioRefineries will apply the research, development, and commercialization of ts parent, Community Bio-Refineries LLC (CBR), to the development of an advanced drop-in-place biofuels. The CBR, which is one of the oldest, privately held biofuels R&D groups in the U.S., was established following the oil embargo of the late 1970s. After studying `gasohol´ (ethanol), the CBR realized there were many problems associated with ethanol as a biofuel and that butanol held far greater potential as a biofuel. The CBR was one of the earliest pioneers in biofuel research and development to further the development of butanol by fermentation. This work subsequently led to butanol research at five major universities, and at the Oak Ridge National Laboratories, where, in 1983, these Collaborators sponsored the first pilot plant to produce butanol as a biofuel since World War II.

Scientists at Oak Ridge became interested in the potential use of butanol as a biofuel and invited one of CBR's prior research entities to sponsor this project. This was the first time a private group of researchers was ever invited into these government labs to conduct research since the development of the atomic bomb under the Manhattan Project. This work was conducted by Dr. Ed Phares, one of the original scientists of the Manhattan Project. Dr. Phares came out of retirement to work with the CBR, to include Mr. Samuel Watson, a scientist who coordinated the butanol research project.

Since that time, the CBR's prior research entities traveled worldwide to develop complementary technologies that can be used to make the fermentation and use of butanol economically viable. Their work in biofuels has been featured in international magazines, journals, and on radio and television coast to coast. In 1980, a USDA sponsored publication featured one of these collaborators as “one of the original pioneers of alcohol fuels in the U.S.” Some of the news outlets that these collaborators were featured in include High Technology Magazine, Mother Earth News, Mayors Weekly, Industrial Technology, Chemical News, The Chicago Tribune, The Des Moines Register, Money Hunt for PBS, Food Engineering Magazine, Beverage World, Food Product Design, Forbes, Dow Jones, and United Press International.

Please Note: Community Bio-Refineries, LLC, and by extension, Hemp-BioRefinery, was created from the reorganization of the former EnerGenetics companies. One of the EnerGenetics investors decided to take over the company just as it was preparing to commercialize. While the charges and allegations levied by this person were shown to be bogus, the drawn-out legal process managed to deplete the funds of the companies and the individuals the lawsuits accused. Eventually, bankruptcy became necessary (which was our nemesis's plan all along). Fortunately, a conversion to Chapter 11 (Re-Organization) was approved by the court, which gave rise to Community Bio-Refineries, LLC. A portion of the funds raised in Phase I of the Offering are designated to protect the new company (CBR) going forward; this is described in more detail within the Sources and Uses section of the Private Placement Confidential Memorandum (PPM).

The Discovery of Revolutionary, New, and Advanced Biofuels

A New Biofuel — 30 Years in Development

This revolution in New and Advanced Biofuels began over thirty years ago when two scientists met at the Department of Chemical Engineering at the University of Toronto in Canada. Working together, they discovered a revolutionary new biofuel process. This process of fermenting carbohydrates yielded two separate products, n-butanol, and triglyceride oils, which, when combined, formed a type of Biofuel never seen before. This discovery was a "eureka moment" for them because the scientists realized they had produced the world's first natural diesel fuel entirely by the fermentation of carbohydrates. They understood the potential of their discovery: it could lead to the replacement of all petroleum-based fuels.

This revolution in Biofuels didn't begin by two scientists at the University of Toronto. The History of Biofuel dates back to the time humankind discovered fire. Wood was the biological source of the fire, the first form of Biofuel, enabling the ancient people to use wood for cooking and heating. It was a German inventors, Nikolaus August Otto and Rudolf Diesel of the diesel engine, which took it a step further. Rudolf Diesel designed his diesel engine to run on peanut oil. Later, Henry Ford invented the Model T car manufactured from 1903 to 1926. This car's body structure and the frame was originally designed and built using Hemp fiber; as a fuel source, it used Hemp oil as the Biofuel to run the engine.

Traditional butanol (also known as n-butanol or normal butanol) is a higher form of industrial alcohol that is produced as a chemical derivative of the petrochemical cracking process. The U.S. demand currently exceeds 400 million gallons annually for use in creating plastics, neoprene, rubber, paint, Styrofoam, etc. World demand is usually ten times that of U.S. demand. Petroleum-derived n-butanol usually contains left-over petroleum contaminants, which makes it an environmental pollutant.

Commercialization of Bio-Diesel Fuels

Shortly after the discovery of this revolutionary new biofuel, the founder of the CBR realized that in order for biofuels to become competitive with petroleum-based fuels and to become a sustainable industry, the volatility of the costs of the feedstock had to be addressed. In the HBR production of cannabis-based products, the focus on the whole plant - from root to bud - is considered. Currently, the cannabis industry focuses primarily on the high value of the CBD oil and THC, which results in the high cost of disposing of carbohydrate-rich waste. The cost of the feedstock and its preparation is usually the highest single cost of producing biofuels and typically accounts for over 50% of the cost to produce biofuels.

The successful research, development, and technology application work the CBR has done will allow the HBR to utilize the entire cannabis plant. The term "entourage effect" is a proposed mechanism to isolate cannabis compounds. The THC acts synergistically with it to modulate the psychoactive effects of the plant. The process of the entourage effect in an HBR is to isolate and recover the starch, sugars, oils, and proteins for energy and health purposes.

Algae and Biofuels

Our late Founder, the first patent holder on biodiesel from organics, possessed significant perspectives in the cultivation and application of simple algae as a meaningful feedstock for food AND biofuel production. While CBR fully intends to continue to pursue his vision, our initial focus will be on more traditional feed stocks and biomass.

Having said that, our quest for suitable biomass for biofuel, even the concept of algae cultivation, appears in the spotlight for biofuel manufacturing due to several positive perspectives such as:

- they do not clash with human or animal food chains;

- very rich with carbohydrate, protein, and oil content;

- can grow in aqueous media such as wastewater, freshwater, saline water, and assimilate nutrients from brackish water, salt water, or highly polluted water,

- demand low water;

- sustain capability to grow whole year naturally with sunlight presence;

- can be cultivated in the waste dump area, sea, ponds, rivers, industrial, and municipal waste drainage, wet bare lands especially in cold regions;

- develop sustainable O2 generation system; and,

- diminish CO2 by up taking it for photosynthesis respiration.

In addition, microalgae contain very short harvesting life cycle and yield nascent biomass that drives higher productivity of the desired biofuel.

More HBR Technological Developments

In the past thirty years, the CBR/HBR Research Collaborators have raised over $20 million to fund sixteen different pilot plant operations at a dozen major universities, and the USDA, to perfect biofuel technologies and establish methods to produce their valuable co-products. Also during this period, the CBR/HBR Research Collaborators received an additional $20 million of in-kind technical and engineering services. These three decades of research have created the world’s first sustainable biofuel business model, which does not require government subsidies for operational profitability.